Currently, a client from Hebei province is in need of high alumina bricks for roasting furnace maintenance. KERUI technicians suggest castable precast blocks for them and explain the reason and advantages of this decision after getting client’s consultation, knowing the working condition and maintenance plan of this furnace in detail, considering the short maintenance period and tight deadtime request, which is agreed by our client totally.

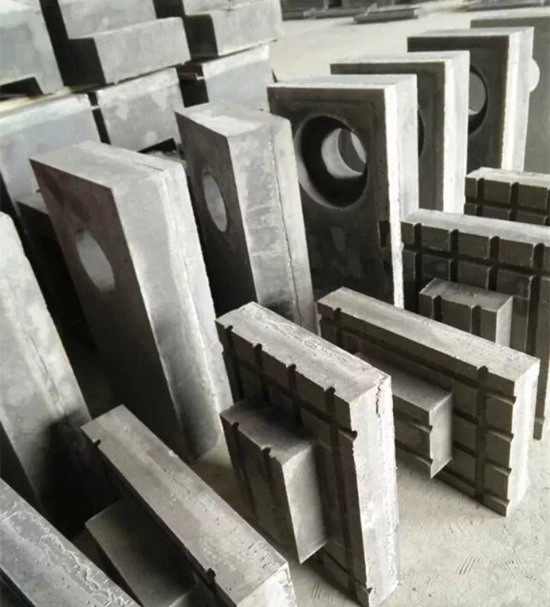

Recently, this batch of castable precast blocks have been finished by KERUI factory and transported to our client for construction. The maintenance of this roasting furnace has been completed successfully. The final acceptance is being done now.

Why do KERUI technical engineers suggest our client use castable precast blocks? Reasons are as below:

1) Short time for furnace repair. The size of each part and assembling method of castable precast block can be designed in advance in our factory according to different furnace types. When the client repairs the furnace, he only needs to adopt reasonable assembling method by crane, forklift or other machines to reduce time greatly.

2) Short time for furnace drying. Castable precast blocks will be dried in KERUI factory first and be designed with scientific assembling structure, such as rabbets, which reduces the amount of refractory mortar. The furnace can be heated rapidly after construction.

3) Good heat resistance, energy-saving. The size of castable precast block is bigger than refractory brick. It is of better heat resistance performance by rabbet connecting without straight seals. Moreover, KERUI adjusts material proportion according to the working condition of this roasting furnace to let it of better strength and corrosion resistance than prime high alumina castable.